Lean transformation

Build a culture of improvement that lasts.

Do you want to create an enduring way of working where leaders, managers, and frontline employees are all engaged in improving how work gets done?

Lean equips teams with the confidence and skills to tackle any challenge. With clear processes, habits of problem-solving, and a shared language and approach to improving performance, you’ll build an unstoppable capability to accomplish just about anything. Leaders become coaches who set direction and develop their people. The organization will develop an operating rhythm that stabilizes today’s work while opening the door to tomorrow’s innovations.

We don’t say “transformation” lightly. We’ll seed and nurture a new way of working rooted in optimism, adaptability, and growth.

Stuck in old patterns?

Without a holistic approach to continuous improvement, you might find:

Leaders spend most of their time firefighting, not coaching

Teams are busy, but not making meaningful progress

Processes feel unstable, depending on who’s on shift

Metrics exist, but aren’t understood or used to guide action

Employees see problems but don’t feel equipped to solve them

Improvement happens only through big projects — and often fades away

Let us guide your journey

We’ll act as your organization’s coach, helping you build the leadership behaviors, management systems, and team practices that sustain change. Our approach includes:

Lean leadership development: Practical training and coaching for supervisors, managers, and executives to model the mindset and routines of a learning organization.

Team-led process improvements: Hands-on coaching that helps teams set and pursue challenging goals, stabilize processes, and adopt daily management practices.

Organizational integration: Facilitated sessions to embed routines like visual management, tiered meetings, and strategy deployment into your operating system.

This combination means leaders learn to lead differently, while teams learn to work differently — reinforcing each other for lasting results.

Lean transformation doesn’t happen overnight. But with a structured approach — and the right coaching — you can build the habits, systems, and culture that keep improvement going, for good.

Benefits include…

A leadership culture grounded in humility, accountability, and scientific thinking

Teams that feel confident experimenting and solving problems at the root

Clear, stable processes that free up capacity for growth and innovation

Alignment between strategy, daily work, and customer outcomes

A shared language and rhythm for continuous improvement across the organization

Learn more about it on our blog:

Case Study: Lean Transformation for a Robotics Systems Integrator

A fast-growing robotics systems integrator found itself constrained by its own success. Customer demand for warehouse automation was rising sharply, but the team struggled to complete projects quickly enough to keep pace. Lead times stretched, work-in-progress swelled, and critical engineering and production staff were constantly firefighting. To grow, they needed to transform the way work moved through the organization.

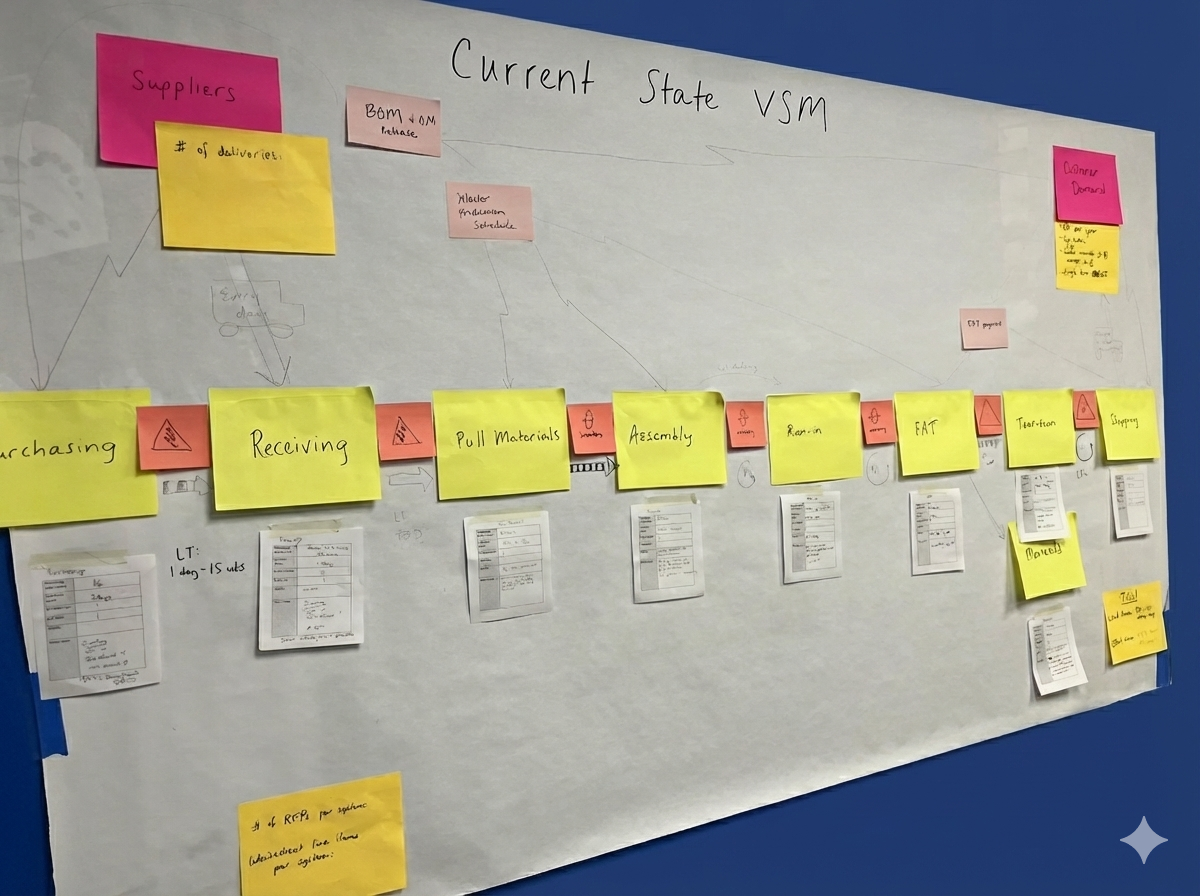

Growing Wild convened a cross-functional team from operations, purchasing, and engineering to map their entire value stream — from material ordering to final system testing. The current-state map exposed bottlenecks, handoff delays, and unnecessary motion. From there, we built a future state that clarified where speed, flow, and reliability needed to improve most. Two improvement kata challenges followed: one focused on reducing issues and unnecessary moves in the test-product process; the other on accelerating pull jobs so materials were ready when needed, cutting job-prep time from five days to one.

Along the way, staff learned scientific problem-solving, practicing daily cycles of experimentation and reflection. We reinforced these skills through workshops on coaching, Lean management systems, and leader standard work — equipping supervisors and managers to sustain momentum and lead the ongoing transformation themselves.

Today, teams are working better together, projects are flowing more smoothly, and leaders are using a shared operating system to guide decisions and problem-solving. As the Operations Manager put it, Laurel’s ability “to keep the group engaged and interactive” helped develop real capability — and the Production Supervisor noted, “You’re the guru…your coaching helped us understand how to apply Lean in different situations.”