Job Instructions: The Missing System Behind Your Goals

January is the month of ambition. Fresh goals. Fresh plans. Fresh energy.

And yet, by the end of the month, many teams find themselves asking the same question they ask every year: Why didn’t this stick?

The answer is rarely effort or intent.

As James Clear famously said: “You do not rise to the level of your goals. You fall to the level of your systems.”

If your systems don’t change, your results won’t either — no matter how good the goal sounded in December.

One of the most overlooked (and powerful) systems you can build is clear Job Instructions.

Why Most Training Doesn’t Actually Train

Here’s the default approach in many organizations:

Step 1: Hire someone new

Step 2: Pair them with a strong performer

Step 3: Say, “Just watch how they do it”

Step 4: Hope for consistency

What you get instead:

Every trainer teaches a different version

Key safety or quality details get skipped

“That’s not how I was taught” debates ensue

It takes a looong time to get anyone new up to speed

That’s because watching is not learning. And memory is not a quality control strategy.

This is exactly the problem Training Within Industry (TWI) was designed to solve. TWI was originally an emergency program of the US government designed to speed up onboarding during WWII, but has since been folded into the Lean management toolkit since it’s such an effective way to embrace standardization while showing respect for people.

Why the TWI Job Instructions Format Works

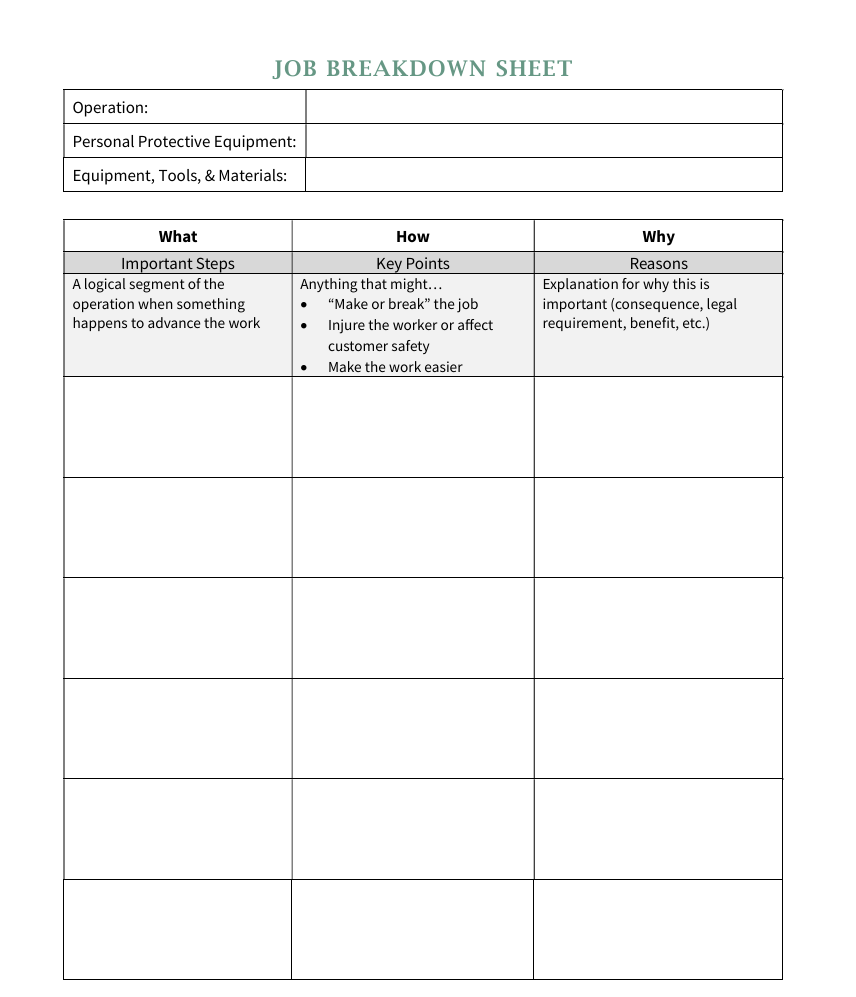

TWI Job Instructions use a simple, disciplined structure:

Download the the editable template here.

Important Steps – the natural chunks of the job

Key Points – to get it done just right

Reasons – why those key points matter

That simplicity is the magic:

It reduces variation: Everyone learns the same job the same way — which stabilizes outcomes.

It protects what actually matters: Key points surface safety risks, quality drivers, and common failure modes that experienced workers often carry silently.

It speeds up training: New hires gain confidence faster, with less rework and fewer errors.

It turns experience into a shared asset: Instead of knowledge walking out the door, it becomes part of the system.

How to Create Job Instructions (TWI-Style)

The best part is, you don’t need to buy a new software tool to get started! Just the focus and discipline to follow these steps.

Step 1: Choose the right task

When starting to create job breakdowns in your organization, pick work that:

Happens frequently

Has a quality or safety risk

Shows inconsistency between people

In production, great examples include machine set-up, a particular sequence of operations, or routine maintenance tasks. Administrative tasks will greatly benefit from this sort of structure, too.

Step 2: Break it into major steps

Think headlines, not keystrokes. You want to capture the stages at which the work advances. Unlike a process flow, you are watching what the operator does, not necessarily what the product does.

Ask: “What are the verbs that progress this work?”

The best way to do this is go see for yourself. Have your most reliable operator show and demonstrate the task. Ops people (not HR people, sorry) should create the documentation using words that users will get.

Step 3: Identify the key points

Key points answer:

Where do people usually mess this up?

What would an expert never forget?

What affects safety, quality, or ease?

You don’t need to include every detail, but reminders for the trainer for what they should be sure to cover. Include the tips and tricks that your best operators have learned over time. “Knowledge is power” doesn’t mean that we keep secrets, but that we share this golden information with everyone - so that each person has the best chance of doing the job successfully.

Step 4: Add the reasons

Reasons make the learning stick.

They explain why — which helps people adapt without breaking the process. So for each key point, include the consequence or benefit of doing it that way.

“Because that’s how we do it” is not a reason. How will the product, the next operator down the line, or the customer be affected by doing it the “right” way?

The Hidden Benefits of Documentation

Far from a bureaucratic exercise, writing Job Instructions exposes things you didn’t know you didn’t know:

Vague expectations

Inconsistent standards – or none at all

Workarounds that became “normal”

Steps no one fully understands

If it feels hard to write, that’s data — not failure. It’s showing you exactly where your processes needs attention.

Systems Beat Motivation

January optimism fades quickly when systems don’t support the work. If you want this year’s goals to survive contact with reality, invest in systems that make the right behavior the easy behavior.

Clear Job Instructions are one of the fastest, cheapest, highest-leverage places to start. I’ve included a TWI Job Instructions template you can download and use immediately. Contact us if you’d like to learn about customized training for your organization.